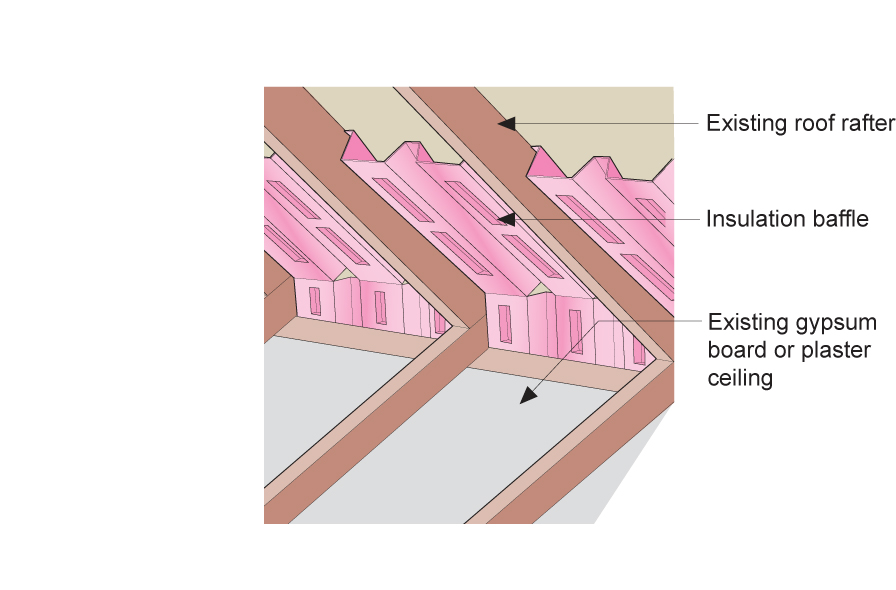

Cathedral roofs especially need a lot more insulation between the ceiling and the rafters because there usually isn t any attic space.

Venting exception for spray foam roofs.

Spray polyurethane foam is a chemical product that is created by two materials isocyanate and polyol resin that will react with each other when they are mixed and will expand up to 30 to 60 times its liquid volume as it is sprayed in place.

Similarly not everyone can afford to spray nearly 10 in.

Roof vents are great for allowing air to move and for removing toxic odours from the home.

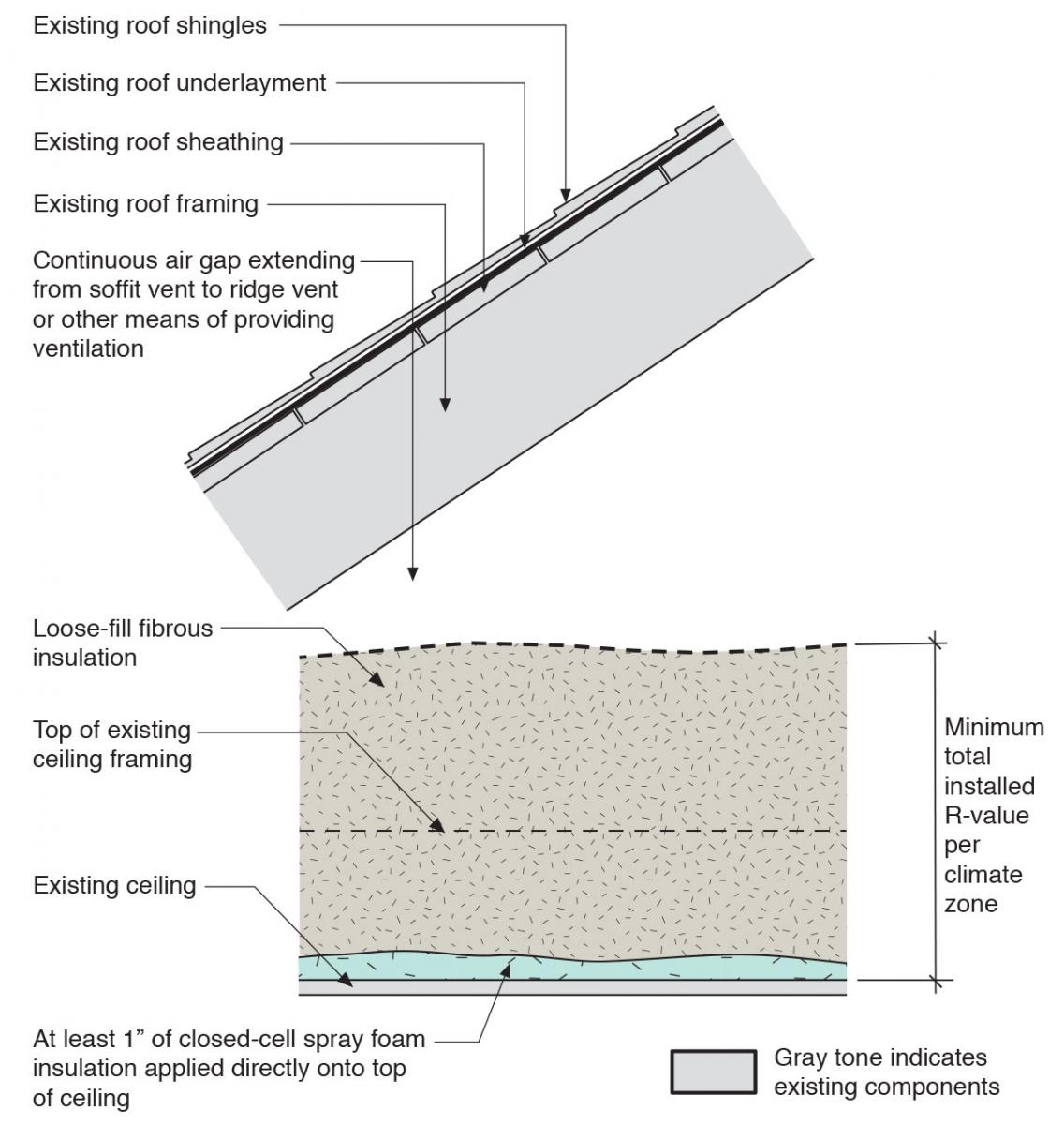

Open cell spray polyurethane foam or closed cell spray polyurethane foam ccspf insulation can be sprayed along the underside of the roof sheathing to provide a conditioned and insulated attic space that can be durable and efficient in.

Of open or closed cell spray foam in their roof or to stack a half foot of rigid foam on the roof deck.

We have the capabilities to spray and inject a variety of foam systems to achieve a high r value while providing both effective vapor and air barriers.

Heat from the house rises up to the attic but when there isn t one the heat rises up to the roof.

An energy recovery ventilator right and a duct distribution box center in a spray foam insulated home.

All insulation materials require proper venting.

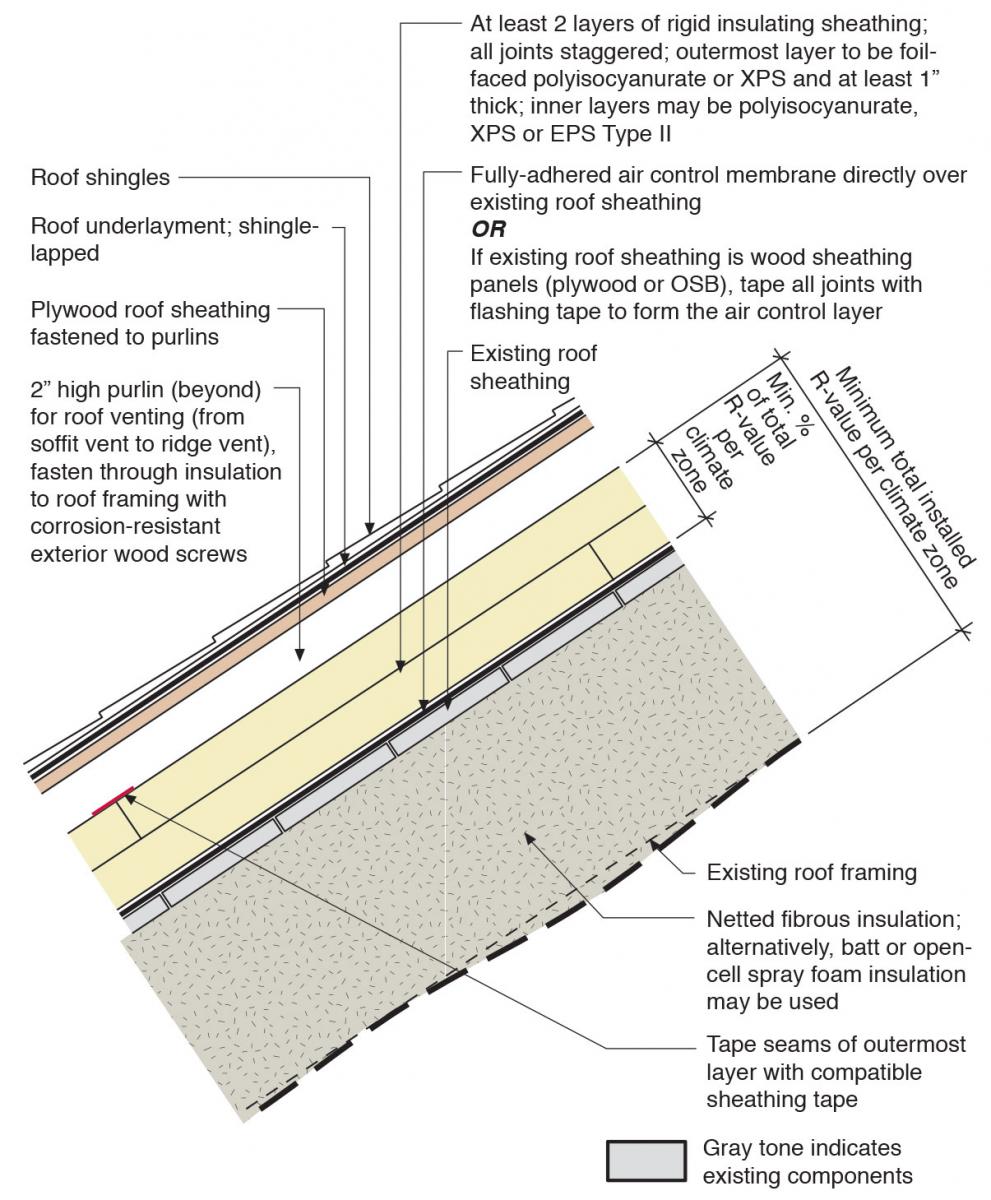

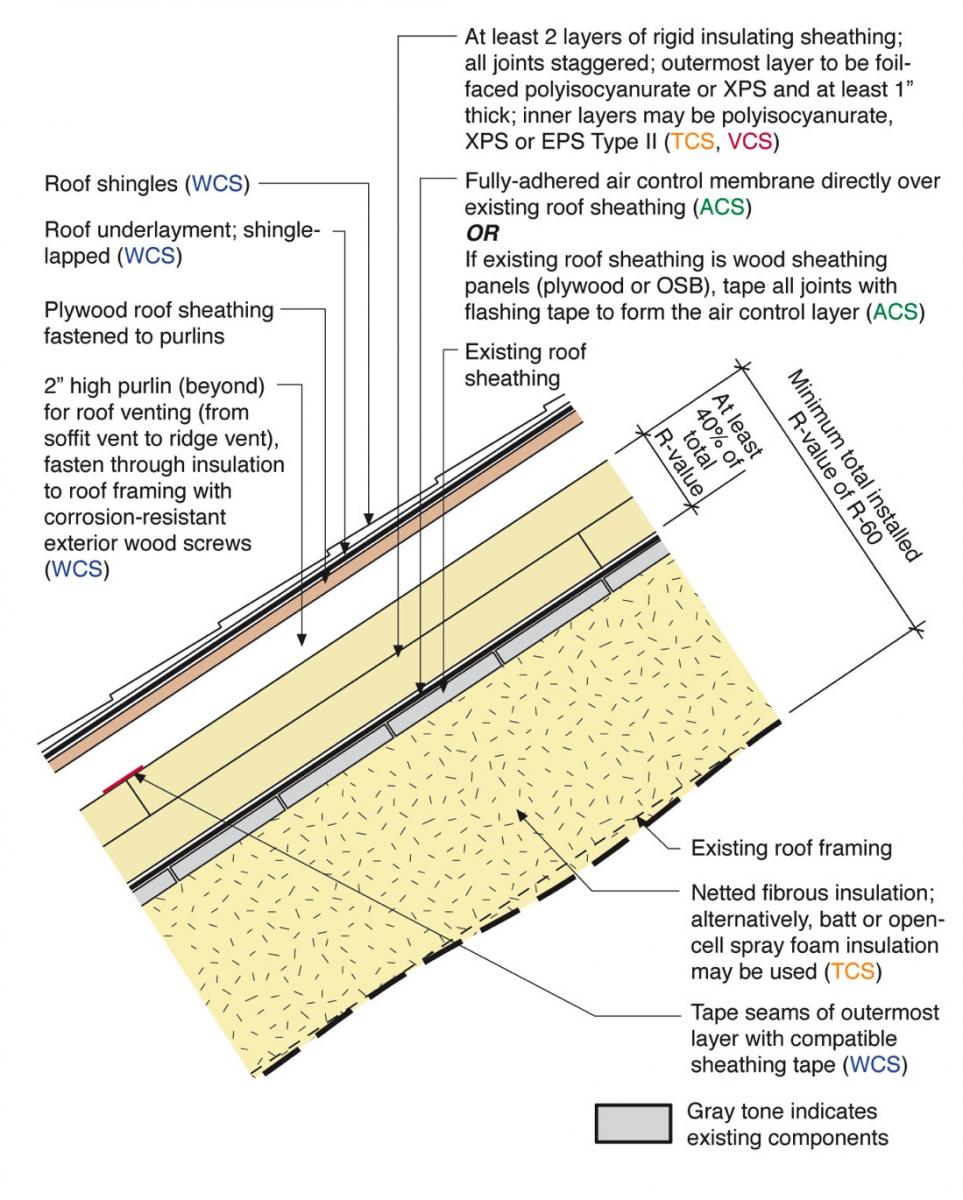

An alternative option is to insulate the rafter bays with a less expensive insulation like fiberglass or cellulose and to control the temperature of the roof sheathing with rigid foam.

However many people think that roof vents cannot be used in conjunction with spray foam insulation.

Unvented roofs with spray foam applied to the underside of the roof deck have been used since the mid 1990s.

If spray foam is used a vent space may still be needed directly under the roof deck.

Foam tech creates superior insulation and environmental control solutions by installing safe cost effective and environmentally friendly polyurethane foams.

Zones 5 6 7 and 8 in that the manufacturers of these materials assume that roof deck may require ventilation to assist drying.

Care should be taken with these assemblies particularly in cold climate zone locations i e.

All of these materials are supported by quality assurance testing capabilities that.

Knowles chairs the astm subcommittee on spray foam roofing and the astm task group responsible for astm c 1029 spray applied polyurethane foam specification.

Rigid foam and spray foam are two of them.

He is a sprayed polyurethane foam association spfa accredited building and roofing inspector and an instructor for spfa courses for applicators and inspectors.